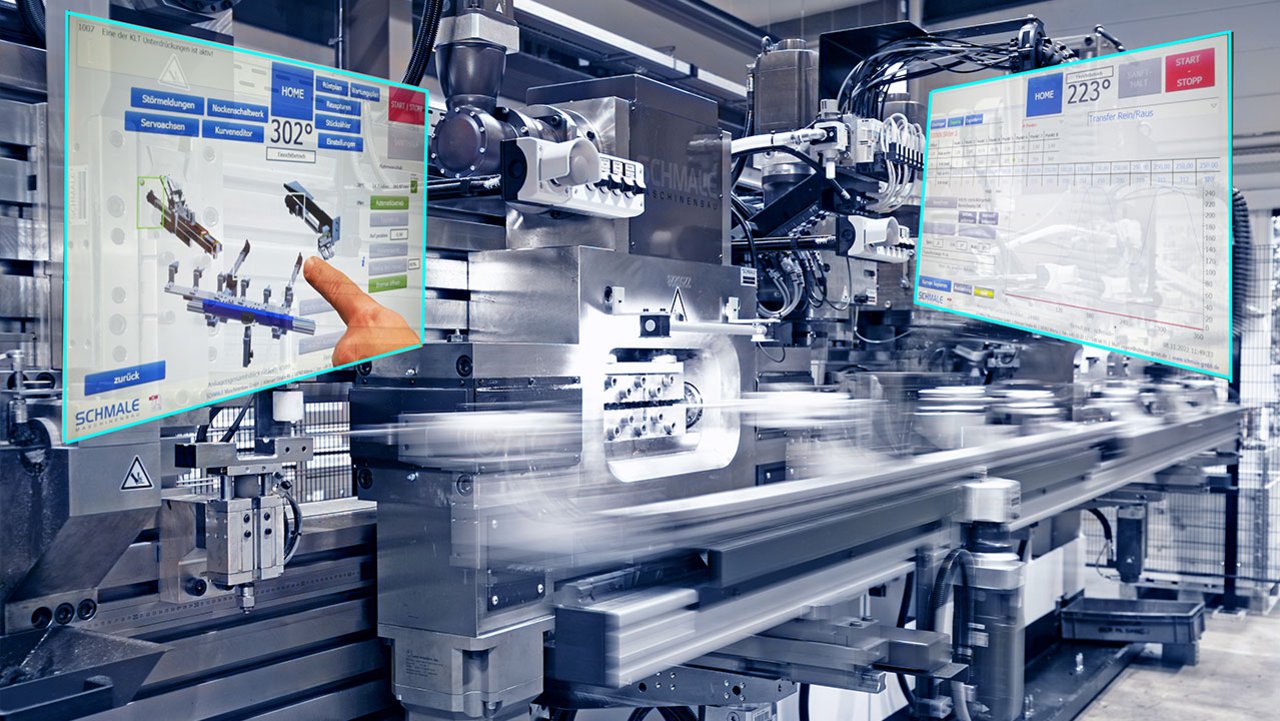

Control technology

Machine construction is also control system design

The task of control system design is to breathe life into machines and forming units, bringing them up to speed while ensuring maximum energy efficiency and motor life.

Servo-electric units with regenerative frequency converters feed unused energy back into the system and make it available for other processes. This way, energy is not wasted as waste heat. Cam optimisation reduces power peaks in the system, resulting in lower overall energy consumption.

At the same time, the system must be easy for the machine operator to use, with an easy-to-understand touch panel. The machine setter should be able to quickly adjust the system via the HMI panel when changing materials or tools, or call up ready-made recipes for modified articles.

The controls from schmale do all this and much more.

The controls and operating concepts are the same for all schmale machines. This means that the training period for the operator is very short. The subsequent, seamless integration of additional functions is guaranteed. As a manufacturer, we place great emphasis on expandability and simplicity. Visualisation of stations, units and processes on the control panel makes the system easy to operate.

Fit for Industry 4.0

Building our own control system makes integration (virtually) limitless. Programming is carried out in close collaboration with the customer. During production, all kinds of data can be recorded, exported in real time and analysed with a view to running a smart factory.