Machines for processing wire, strip and tube

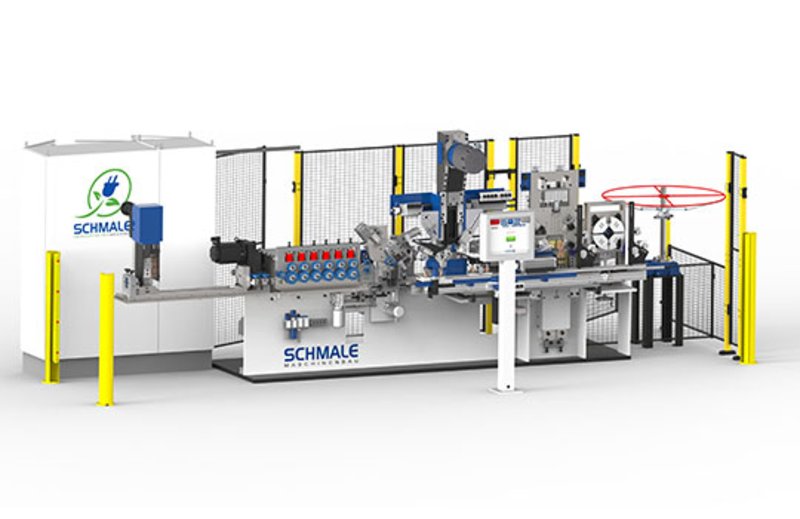

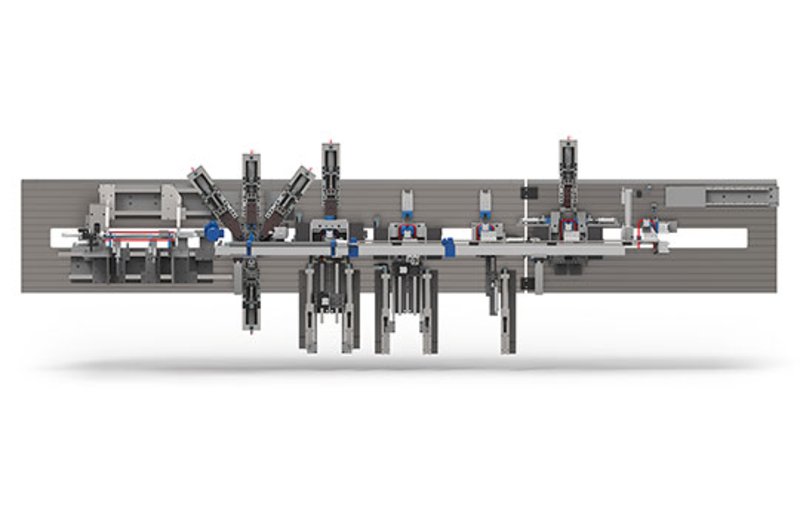

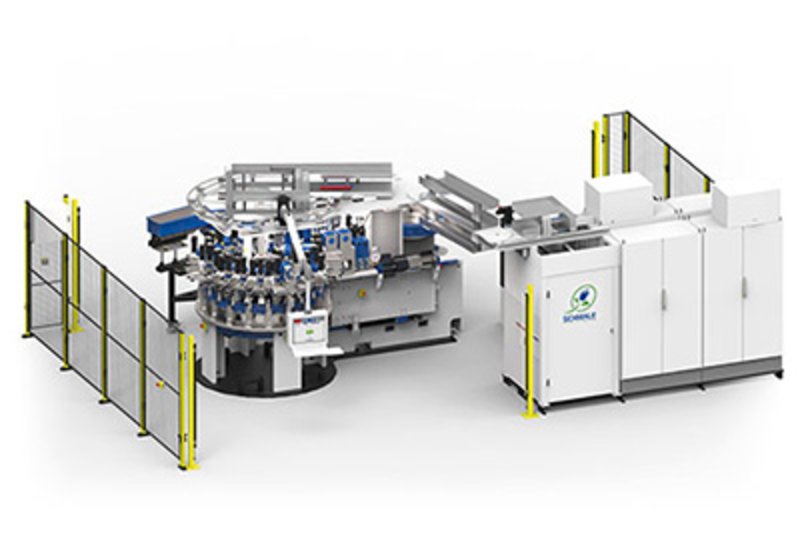

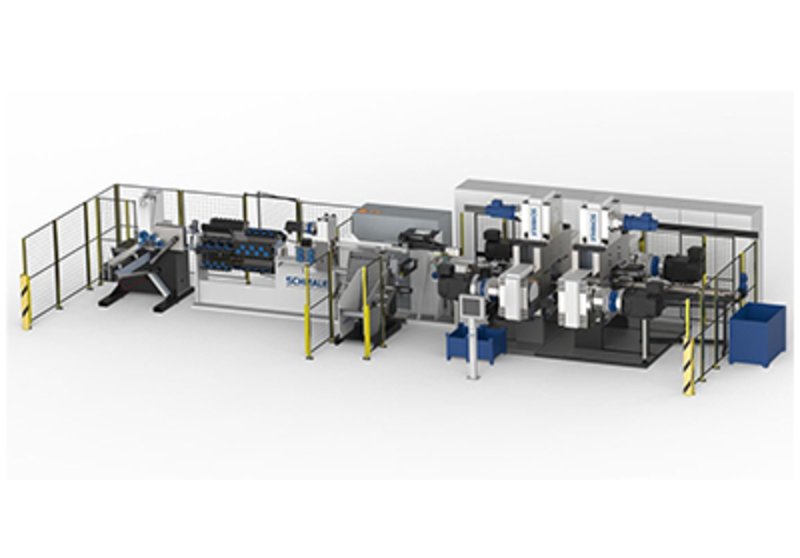

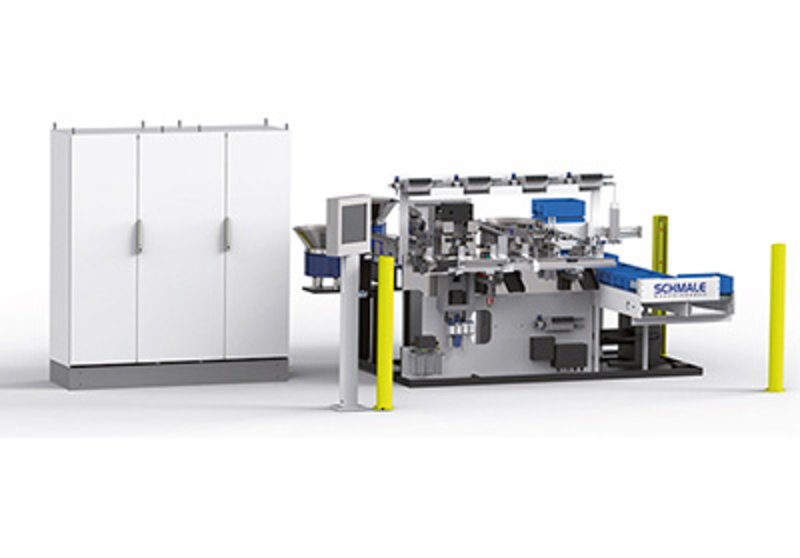

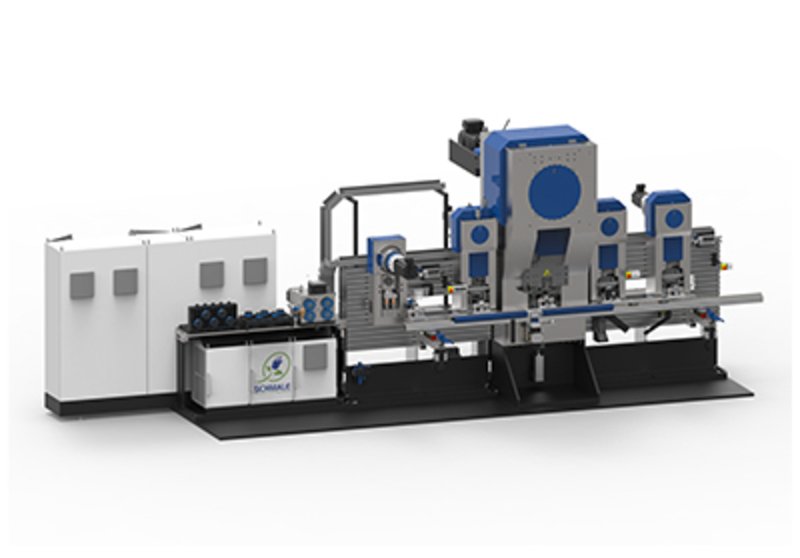

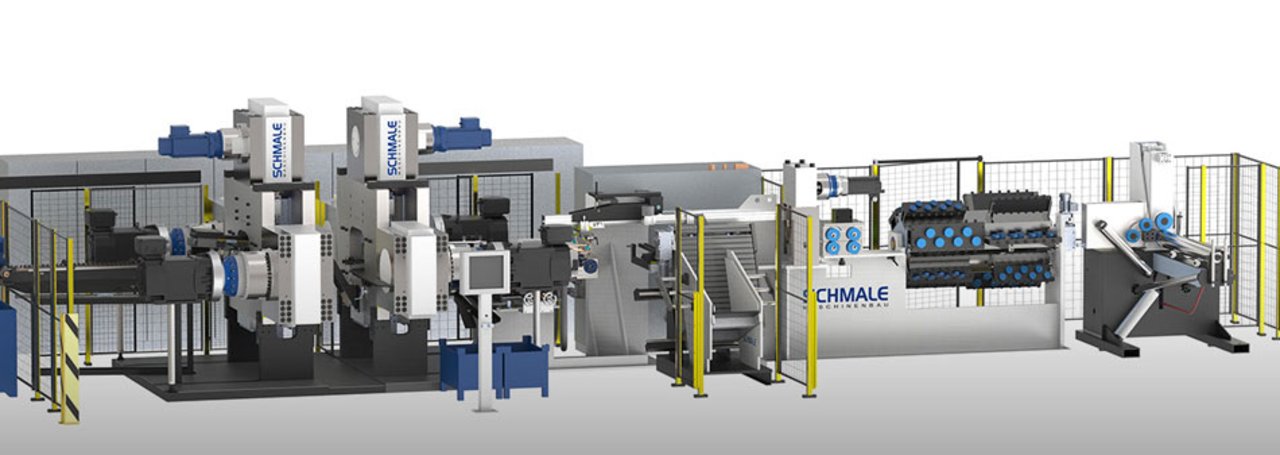

schmale Maschinenbau GmbH is one of the leading manufacturers of wire bending machines and tube bending machines. We integrate a wide range of forming technology units into our modular punching and bending machines.

Our systems combine NC benders, servo presses and bending slides with a servo-electric transfer system. This creates customised solutions for automating manufacturing processes.

In the world of schmale machines, you will find modular, customisable standard machines for a wide range of production tasks in forming technology. We are one of Europe’s leading machine manufacturers in the field of wire, strip and tube processing.

For forming processes that cannot be carried out on our standard solutions, we develop appropriate special-purpose machines.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.

Testimonials from our customers and partners

"The machine concept from Schmale Maschinenbau gives us the opportunity to produce components using different production processes that are fully interlinked.

The increased complexity of the parts combined with a high level of cost-effectiveness offers us the opportunity to serve new market segments!"

Michael S.

Fa. M. / Altena

"It's truly impressive...Enthusiasm for the technological implementation.... It's great to see that it works, and that such an innovative venture was completed successfully. Throughout the collaboration, you could also sense that there was a certain pleasure in the engineering work. Pleasure in somehow overcoming the limits that had previously existed.”

Philipp Maurer

Wittenstein cyber motor (on working together to develop the Speedmax)