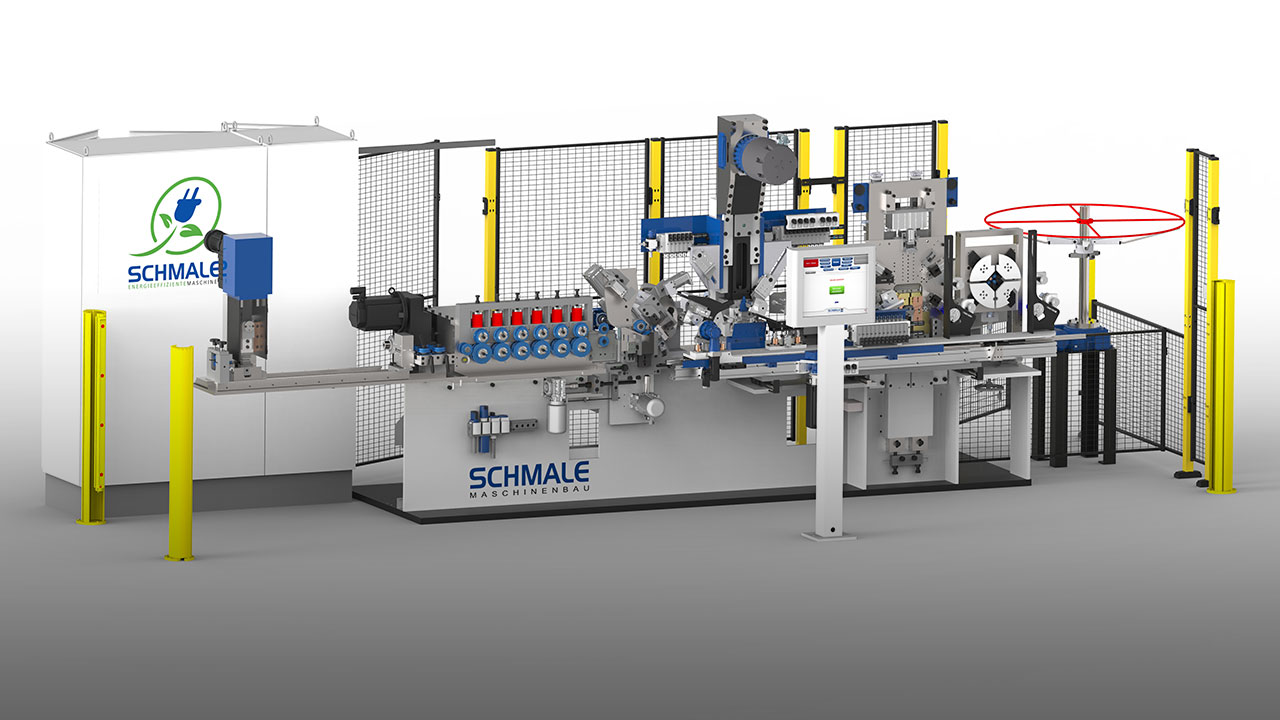

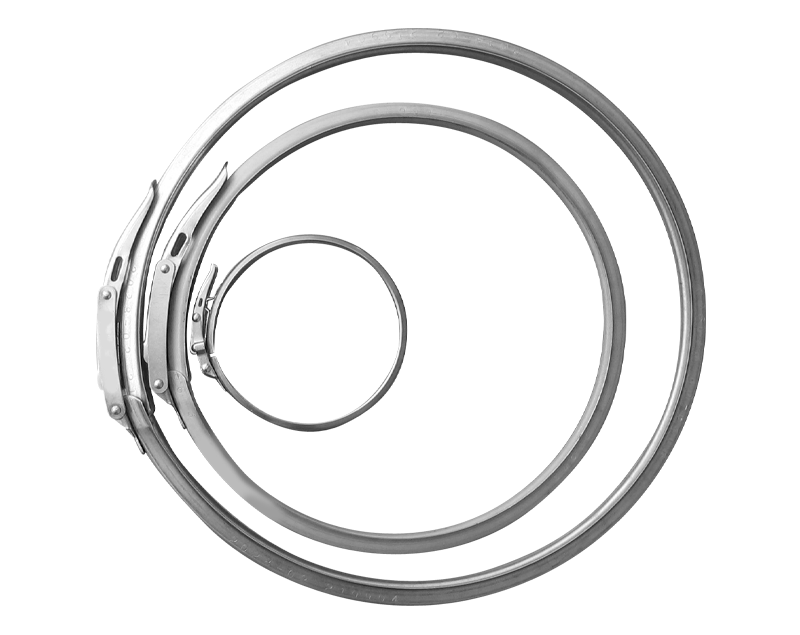

Clamping ring machine

A clamping ring machine is a system for the automatic production of clamping rings. schmale Maschinenbau Gmbh is one of the leading manufacturers of automatic clamping ring machines in Germany.

Our clamping ring machines profile, bend and cut the strip material. Closures are automatically fed and welded on. The finished clamping ring is calibrated and deposited. All processing stations are connected to each other via a servo-electric transfer and are operated simultaneously. /Cycle rates of up to 28 clamping rings per minute can therefore be achieved.

Our clamping ring machines can be equipped with different tool sets and, after a brief changeover, they can produce clamping rings with different diameters.

Technical data

| Drive technology | Servo-electric |

| Wire | |

| Strip | |

| Pipe | |

| Servo-electric feed roller | |

| Hopper conveyor | Decoiler | - | |

| Piece capacity | 0 to 28 |

| Typ. wire diameters | |

| Typ. strip dimensions | up to 50 x 3 mm |

| Free work surface | |

| Transfer system | |

| Stations max. | 6 |

| Force functions | up to 5 |

| Typical forces | up to 150 kN |

| Servo axes | approx. 15 |

| Standard hydr. function | 0 |

| Teleservice | |

| Power requirement approx. | depending on version 15-30 kW |

| Weight approx. | 10 t |

Related topics

Clamping ring machines are highly specialised SPECIAL-PURPOSE MACHINES for strip processing. We have a wide range of products in this field, please take a look at our video.

Comparison between mechanical and electronic cams

In the design of modern automatic punching and bending machines, mechanical cams are increasingly being replaced by electronic cams. This is because electronic cams are much more flexible than mechanical cam drives. This becomes particularly apparent when product parameters need to be changed. With mechanical cams, the entire cam has to be replaced in such cases – a process that is, of course, very costly. Electronic cams, on the other hand, allow the new parameters to be easily programmed in with minimal data. In addition to the greater flexibility offered by electronic cams, there is another advantage: electronic cams allow significantly higher cycle times than mechanical versions, thus increasing the productivity of the machine.

Electronic cams in punching and bending technology

Electronic cams are an integral part of modern machines in process technology. They have long been established as drive technology and are known to offer a number of advantages over other processes. The principle of electronic cams is based on the calculation of motion profiles, which are transmitted to the machine's control system as tables or parameters. A system using electronic cams requires powerful software to achieve optimum motion sequences. This is the only way to ensure that the machine operates smoothly, effectively and with low wear. The fact that a control system using electronic cams can also generate extremely high forces is demonstrated by the 2000 kN NC press from schmale. The machine is conveniently operated and programmed by entering just a few items of data via touchscreen. In a fraction of a second, the machine then generates the electronic cams required to control the servo-electric axis. When designing the system, schmale deliberately developed a user interface that delivers the desired results in a simple and transparent way. This makes it possible to work with the new technology quickly and conveniently from the very first commissioning, without the need for lengthy training periods.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.