Production of headrest support brackets

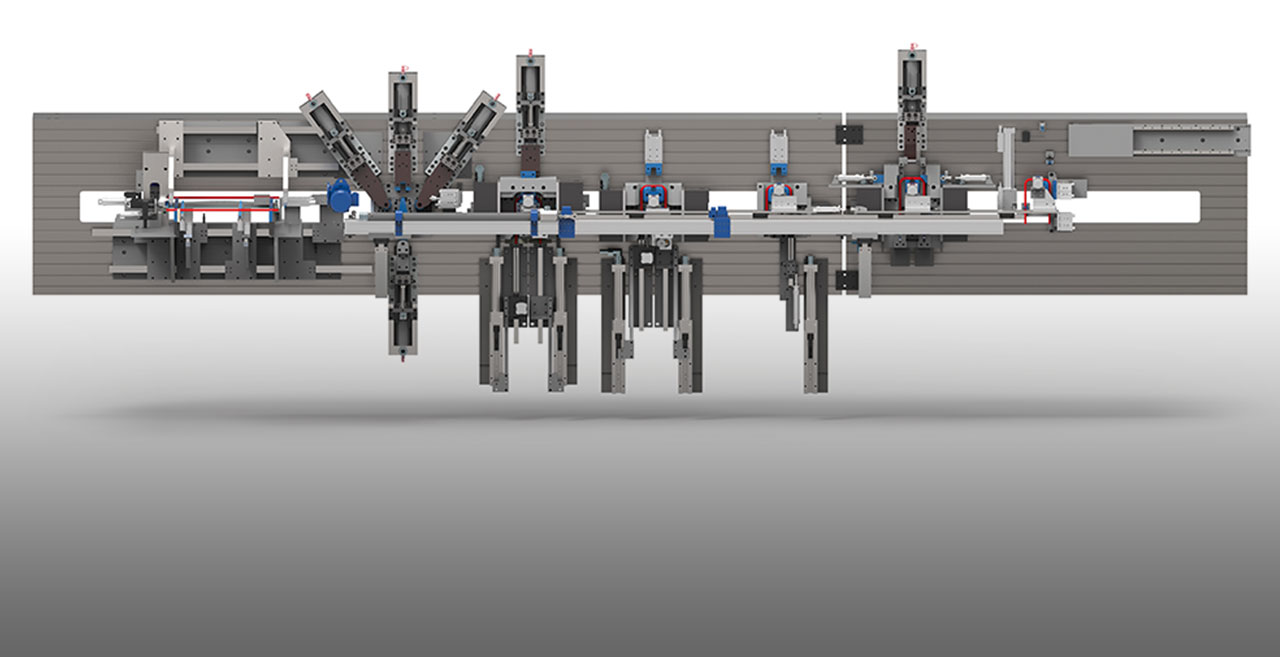

The production of headrest support brackets from wire or tube is automated on the wire/tube bending machines from schmale Maschinenbau GmbH, in individual stations equipped with servo-electric bending slides or CNC finger benders. Multiple bending operations can be carried out simultaneously or consecutively on our X2000NC production lines. In addition to bending, the other work steps such as chamfering, notching and swaging are carried out automatically on one system.

As a leading manufacturer of modular, automated systems for wire, tube and strip forming, we combine and install units for all industrial forming processes on one machine.

Technical data

Tool set

6 stations for embossing, bending, notching and swaging tube material on a 6 m back wall, tube sections fed via hopper conveyor

Our machines operate at high speed. For more information, please contact our Sales department.

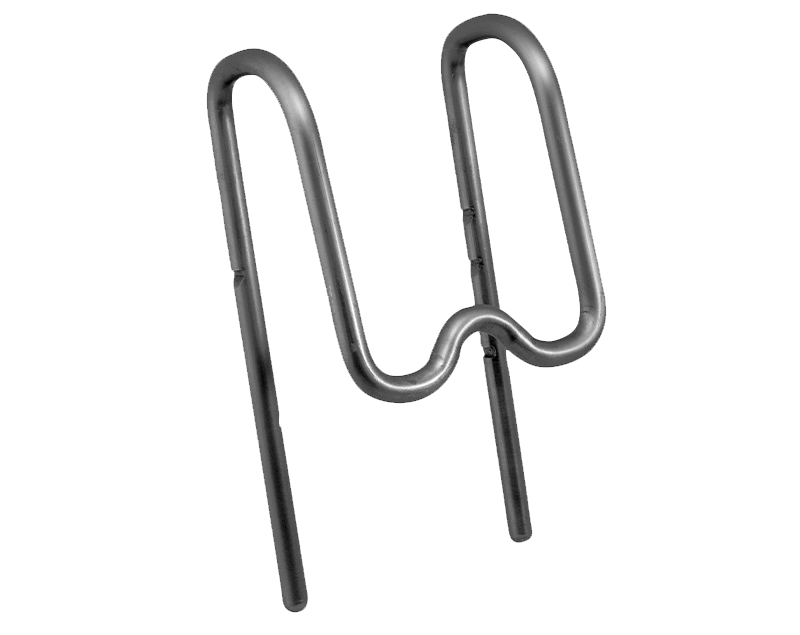

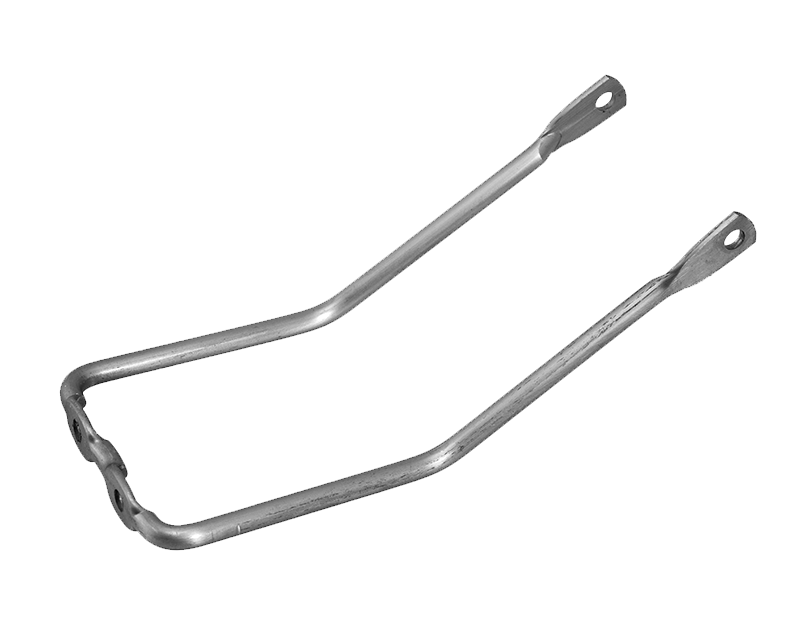

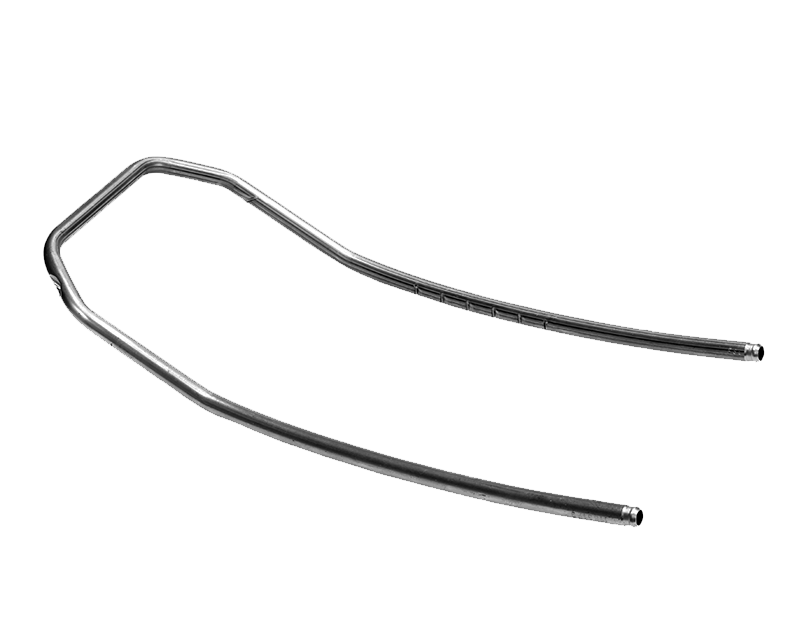

Headrest support brackets - essential for safe driving

Since 1999, headrests have been mandatory in the front seats of passenger cars in Germany. In the standard version, headrest support brackets made of bent wire tubing are inserted into the seats, in different versions depending on the car model. These are used to attach and adjust the headrests to the seats. In the event of a rear-end collision or hard braking, headrest support brackets prevent the head from being jolted backwards. This helps to prevent injuries to the cervical spine, e.g. due to whiplash. It is important to adjust the headrest support bracket correctly: the upper edge of the headrest should be level with the top of the head. In terms of safety, headrest support brackets are therefore a key component in ensuring the protection of the driver and front passenger. As a result, the quality and reliability requirements placed on car manufacturers for headrest support brackets are extremely high. As visible components in the vehicle interior, headrest brackets also have to fulfil stringent visual requirements. Bending machines used to produce headrest support brackets must meet similarly high standards.

Headrest support brackets produced by machines from schmale Maschinenbau GmbH

schmale system technology provides its customers with innovative machines for a wide range of technologies. Headrest support brackets can be produced efficiently, economically and in excellent quality on schmale bending machines. schmale provides its customers with the tailor-made machine that they need to produce their headrest support brackets. For example, the headrest support brackets from schmale have a tube diameter of 14 x 1.5 mm and are produced ready-to-use. The power required by a schmale bending machine to produce headrest support brackets is approximately 30 kW. Part ranges with different leg lengths and minimal tooling requirements are feasible. Thanks to the servo-electric drive technologies developed in-house by schmale, the machines are exceptionally energy-efficient, consuming on average 50% less energy than other machines. When designing an automatic bending machine for headrest support brackets, it’s not just the customer’s individual production profile that is taken into account. Machines from schmale are usually designed in such a way that the customer has the option of implementing subsequent development stages.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.