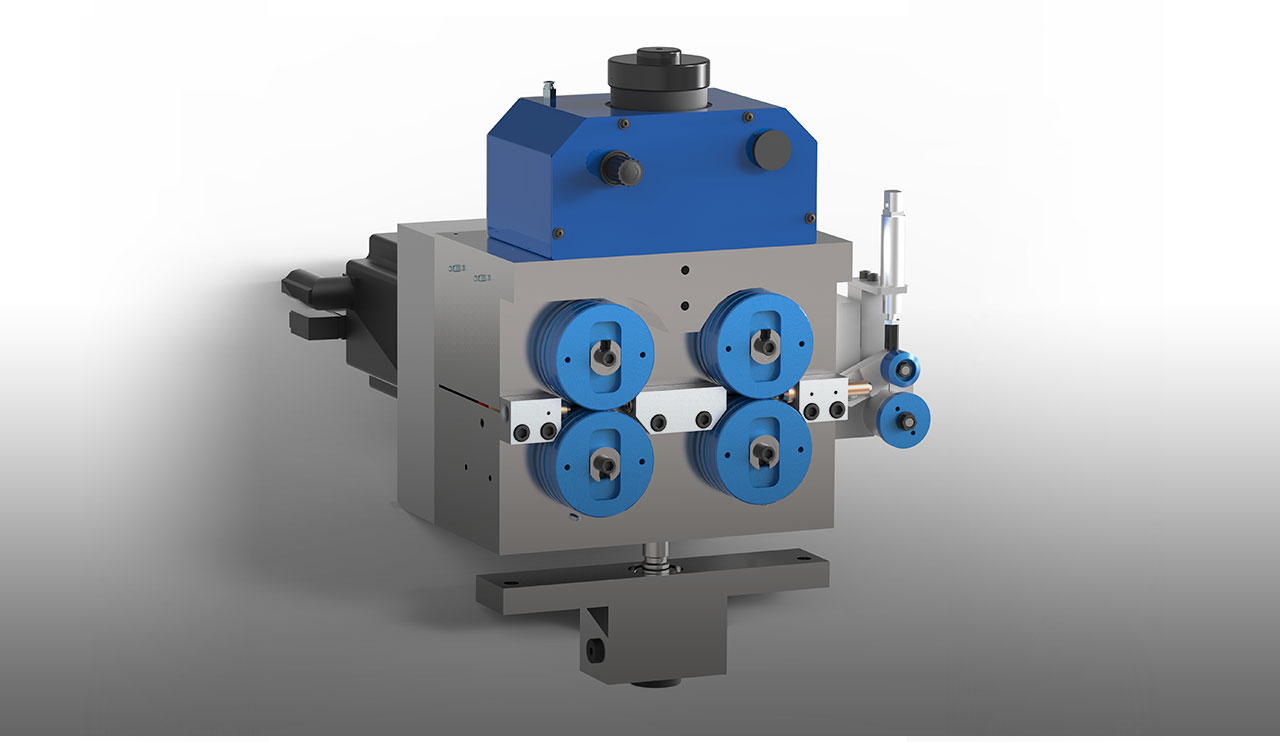

Servo-electric units

As a specialists in complex forming systems and special-purpose machines, we place special demands on our units. Demands that standard units often cannot meet. For this reason, we also design and build servo-electric special units for a wide variety of applications according to customer specifications. One of our areas of focus is in the field of decoilers/special decoilers.

We design and build custom decoilers for demanding requirements. Coilers that are not available as catalog items from other suppliers.

Our portfolio includes servo coilers, heavy-duty coilers, and reversing coilers. A video on our YouTube channel shows various application examples for such coilers. And that is just one example. We also have exactly this expertise in the design and construction of other customized units.

We have a schmale solution for every problem.

Drei Beispiele für Sonderhaspel

Three examples of special decoilers

Servo motors in punching and bending technology

The use of servo motors in punching and bending technology has opened up new production possibilities. While traditionally driven machines can operate at high speeds and produce correspondingly high volumes, product variety remains limited. In addition, mechanical machines can only be converted at great expense and maintenance is often more complex. In contrast, servo-driven bending machines, such as the X2000 NC from schmale Maschinenbau,https://www.schmale-gmbh.de/maschinen/x2000nc.html offer much greater flexibility in terms of product variety, with low maintenance requirements. In addition, machines driven by servo motors cater to changes in customers' logistics strategies. Whereas in the past, the emphasis was on large, long-term storage facilities, today stocks are generally kept lower in order to save costs. The result is smaller orders that need to be filled quickly promptly and to which the manufacturers need to be able to respond quickly.

schmale Maschinenbau - Innovations with servo motors

With the introduction of the X2000 NC, schmale has launched a fully servo-electric machine on the market for the very first time. The model has a number of advantages over mechanical or hydro-mechanical systems, not least due to the installation of the servo motors. For example, the X2000 NC, X2000 BB and X2000 BK models with servo motors are much easier and faster to program than purely mechanical systems. In addition, the servo motors ensure greater material protection. The quality of the end product also benefits from this technology. Short set-up times, high cycle rates, reduced space requirements, reduced energy requirements and high energy efficiency are all characteristics of production systems with servo motors. Machines with servo motors also allow the integration of existing mechanical moulds. The X2000 BK from schmale Maschinebau is also able to use standard Bihler tools. This further increases the range of products that can be manufactured and significantly reduces changeover times. Even small batch sizes can be produced easily with little time and cost.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.