NC benders

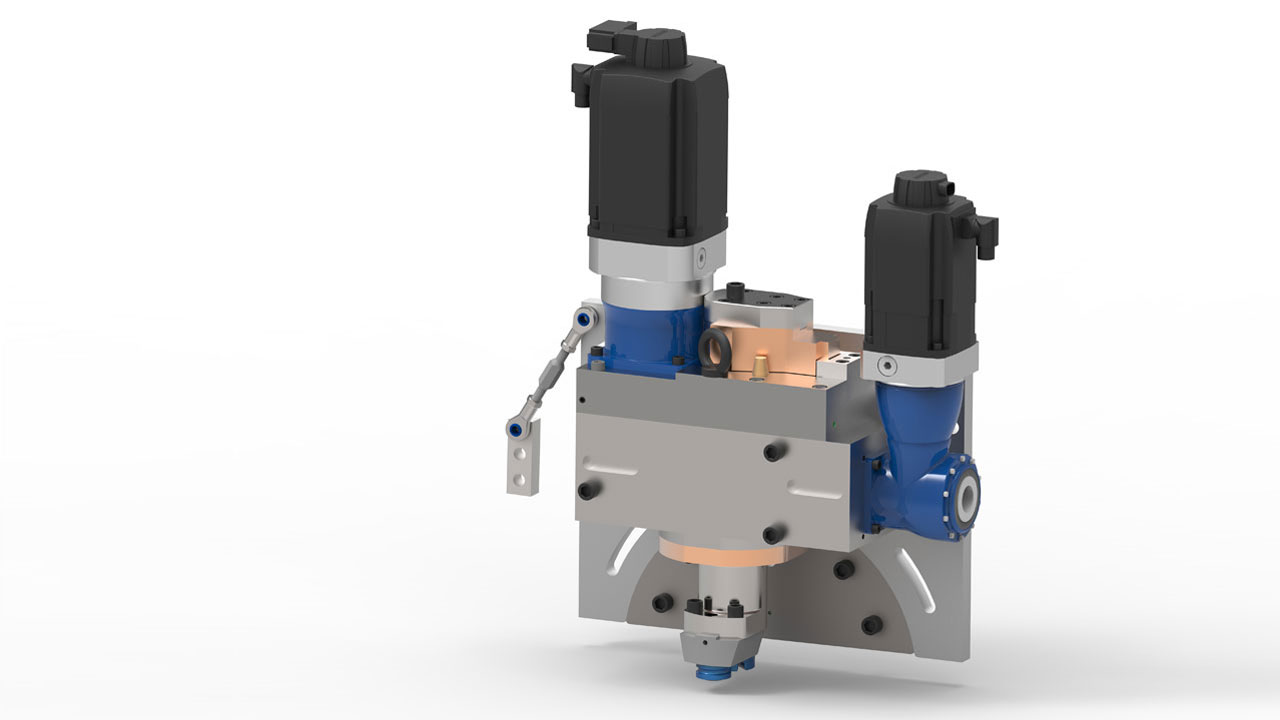

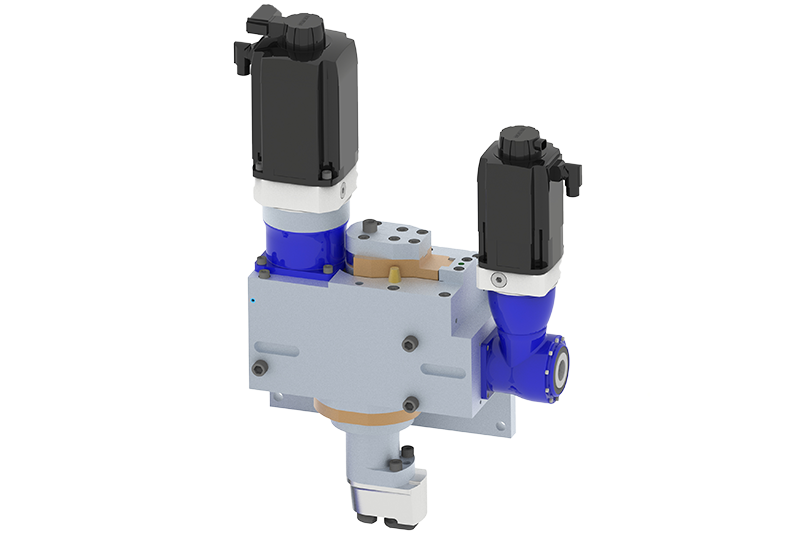

NC benders or servo-electric finger benders are cold forming units which we install in our systems. The main advantage of NC bending technology is the short set-up time for tool changes. In our systems, we usually combine NC benders with rotary positioning clamps and our servo-electric transfer to achieve maximum performance.

We install NC benders with forces of 30 – 200 kN in our forming stations for hot and cold forming.

Cold forming with servo-electric NC benders or finger benders combined with rotary positioning clamps is a modern method of producing high-precision bends in wire, metal tubes and profiles. This technology has gained prominence in recent years since it allows bends to be made faster and more accurately than with traditional methods such as manual bending or hydraulic bending machines can produce.

In this method, the material to be bent is inserted into the bender, where it is held in place by a rotary positioning clamp. The servo-electric NC benders or finger benders then ensure that the material is bent precisely and evenly. The unique feature of this technology is that it enables high-precision control of the bending processes, resulting in better repeatability and higher product quality.

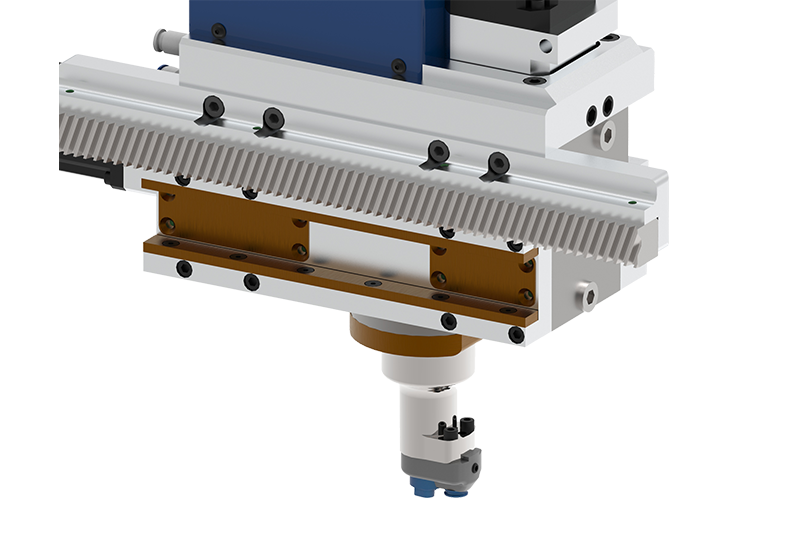

Another advantage of this method is that it offers great flexibility in the design of bends. By combining different bending angles and radii, complex shapes can be created that would be difficult or impossible to produce using traditional methods. This flexibility also makes it possible to respond to customer requests quickly and efficiently, as changes to the bends can be made easily.

The bending tools are inexpensive and a tool change can be carried out in minutes, keeping downtimes for product changes to a minimum. This also makes it possible to produce a variety of items and small batch sizes.

Thanks to the precise control and high flexibility, this technology can be used in a wide range of applications, ranging from the automotive industry to furniture manufacturing. In addition, cold forming with servo-electric NC benders or finger benders combined with rotary positioning clamps also offers economic benefits. It enables faster and more efficient production, resulting in lower costs and increased profitability.

Overall, cold forming with servo-electric NC benders or finger benders combined with rotary positioning clamps is an innovative technology that has revolutionised the production of high-precision bends in wire, metal tubes and profiles. It offers higher quality, flexibility and efficiency than traditional methods and can be used in a wide range of applications.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.