Speedmax

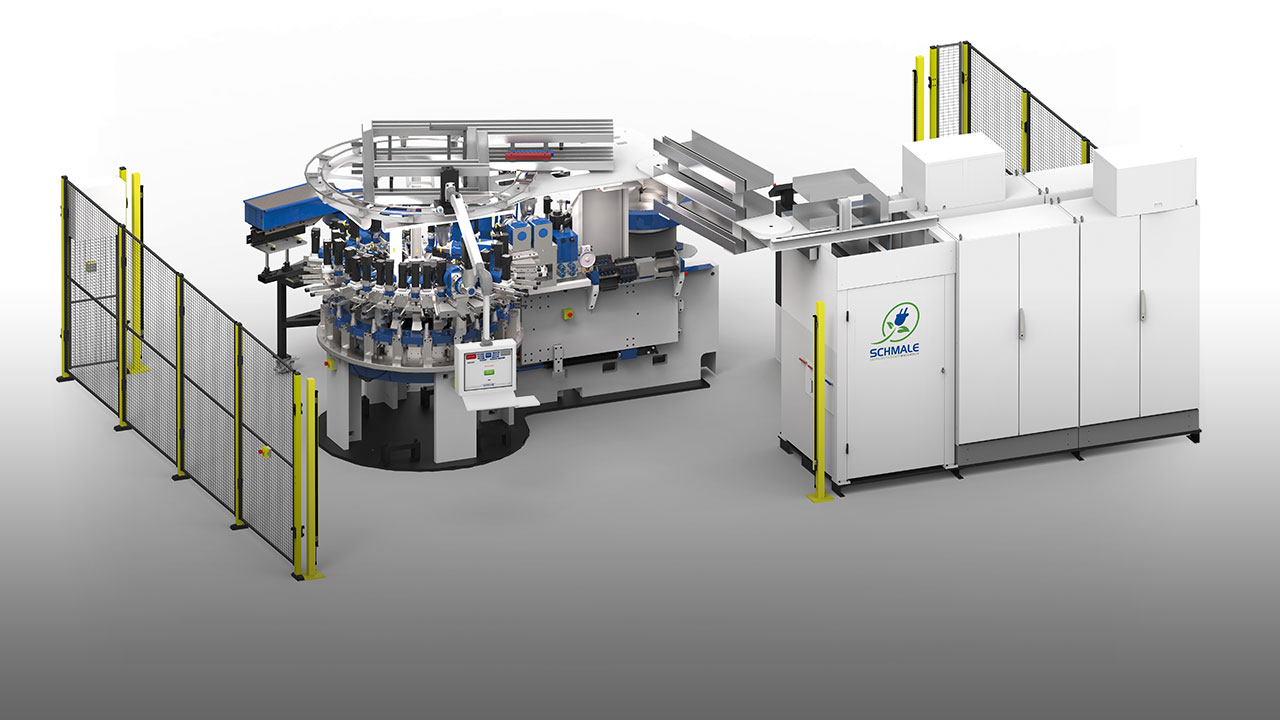

The high-volume bending automation solution.

Our Speedmax is more than just a bending machine. It is one of the fastest automation solutions for wire and tube forming available on the market for NC bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax, with up to 90 servo axes, can achieve a speed of up to 4000 machining steps per minute.

Technical data

Machining stages / cycle rate

The SPEEDMAX at its current stage of development has 20 machining stations and can produce up to 200 parts per minute.

Tooling time / tooling requirements

The tooling time for an article change, for example with 3D bends, is only a few minutes for the same material cross-section.

Technologies

The following production technologies can be implemented on the 20 machining stations: bending, embossing, notching, flattening, joining, punching, swaging, etc.

(of tubes and wires)

In its current stage of development, the SPEEDMAX S has 20 processing stations and can produce up to 200 parts per minute. It combines the advantages of the NC and slide-based wire bending concepts without the disadvantages of either.

Each individual station completes its task in less than 0.2 seconds. The separate transfer allows all stations to operate simultaneously. This allows the machine to ultimately produce more than 3 finished parts per second at the maximum cycle rate. Each with up to 20 bends.

At a reduced cycle rate, even multiple bends are possible at each station. So the number of bends per part is not limited to 20.

In 2019, the SPEEDMAX L was voted by the readers of MaschinenMarkt magazine as one of the best products of the year 2019 in the "Forming Technology" category.

It currently has 20 machining stations and can produce up to 60 parts per minute. It processes tube and solid material up to a diameter of 12 mm and an infeed length of 500 mm. Different bends in all planes and, in its current configuration, up to four swaging processes are not a problem. Of course, different configurations of the SPEEDMAX L also allow for embossing, notching, flattening and punching.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.