Bending slides

Bending slides, also known as bending sliders or slide units, are machine components used in the production of punched and bent parts. High-quality punching and bending machines require absolutely reliable components with a long service life. The bending slide must be robust, reliable and powerful.

The bending slide as a component of punching and bending machines

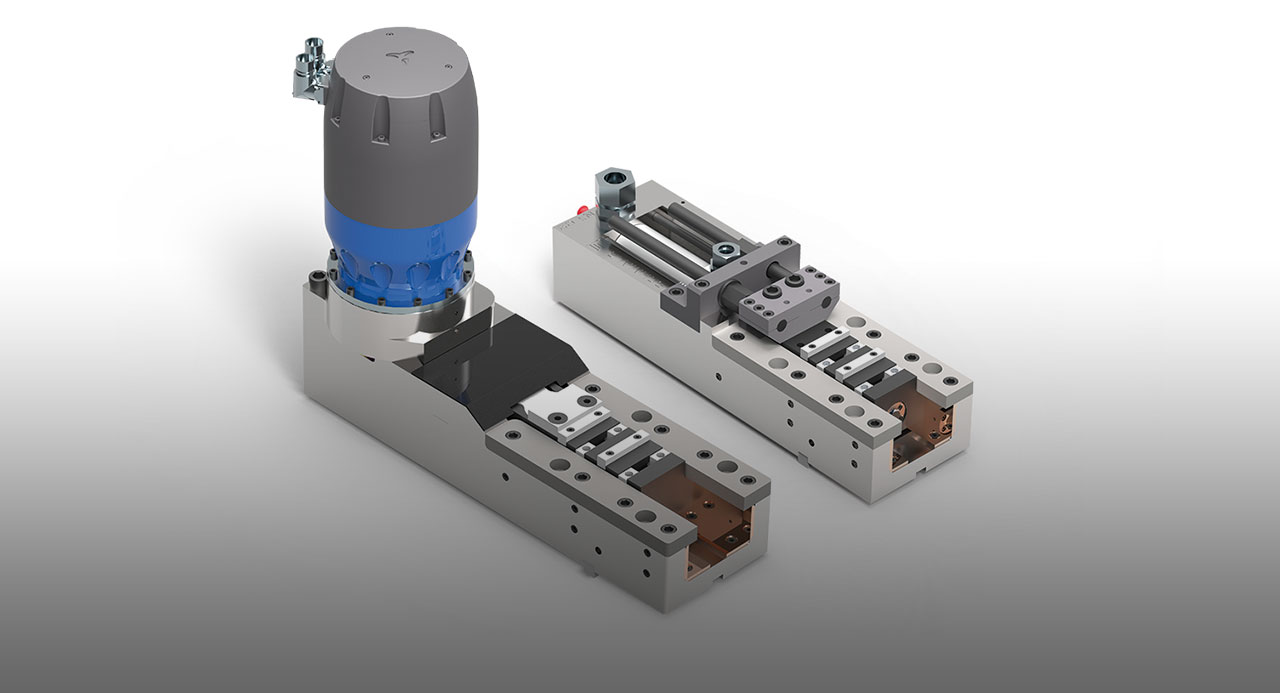

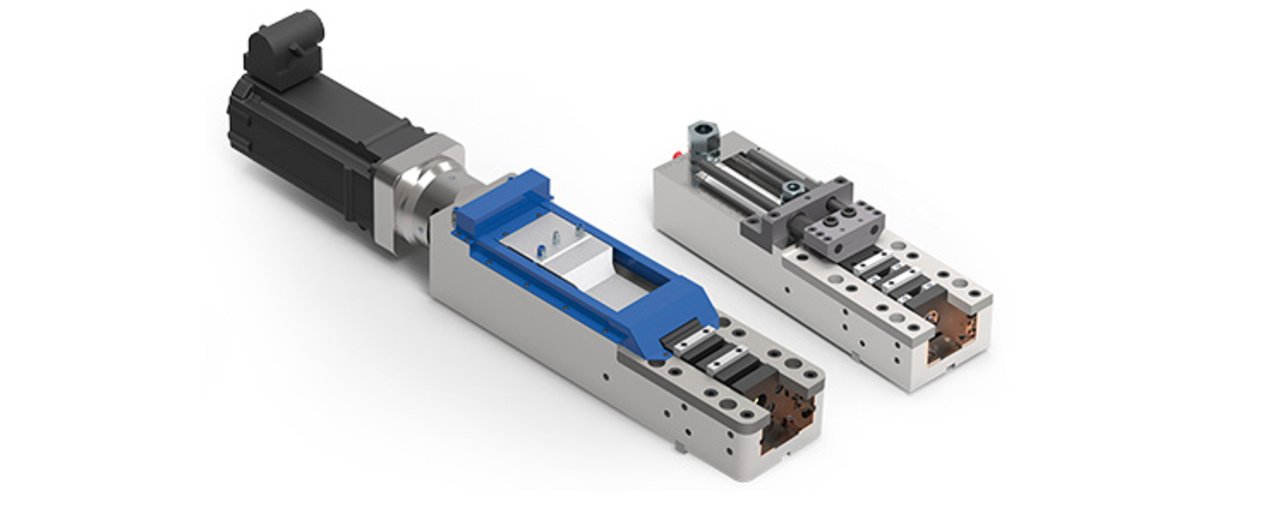

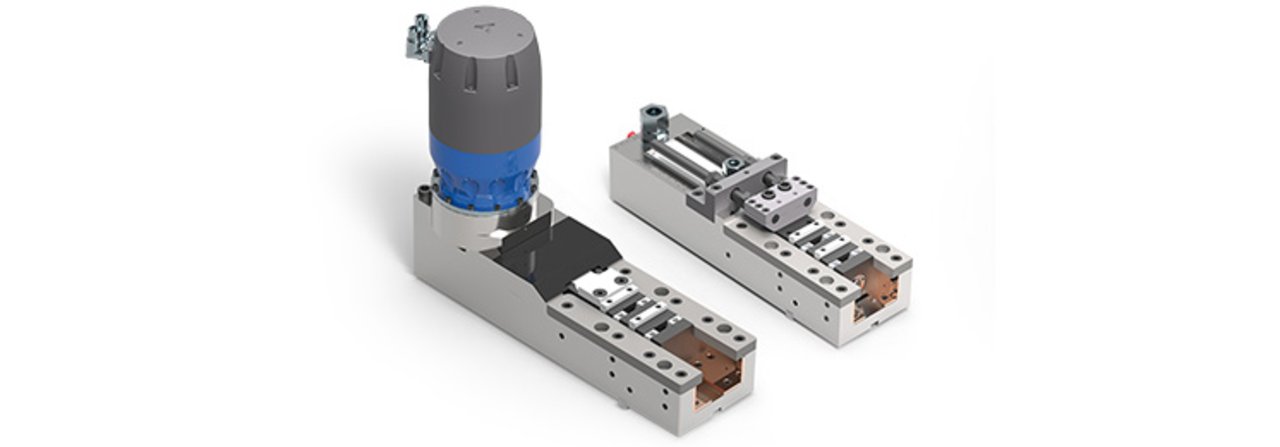

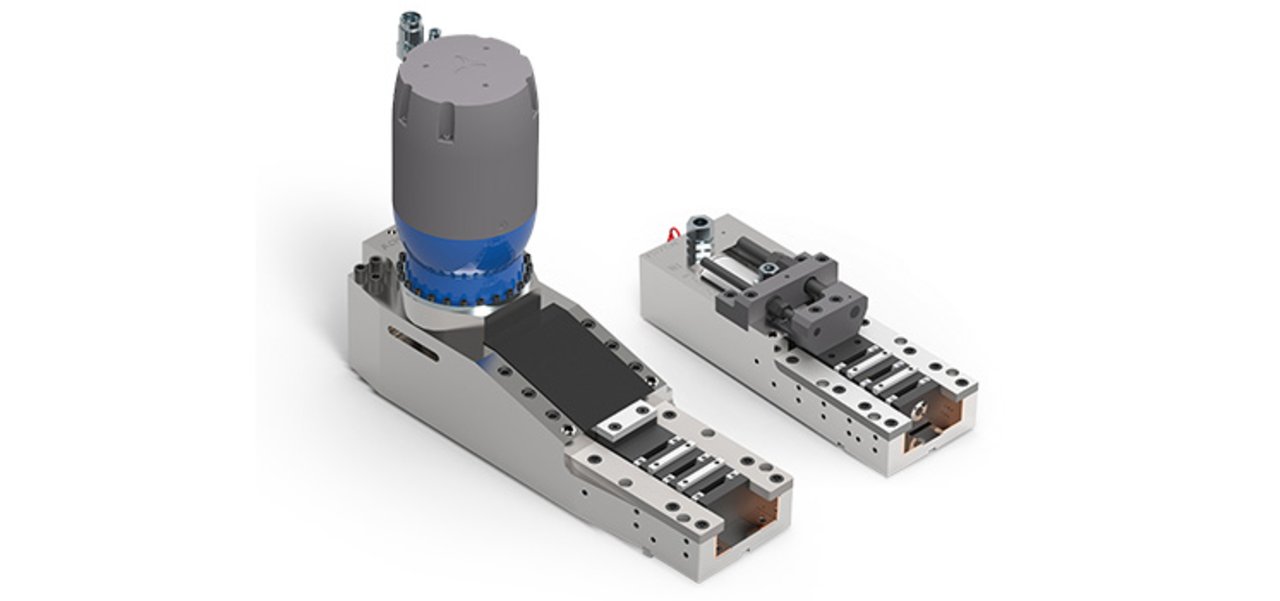

Bending slides, also known as bending sliders or slide units, are machine components used to produce punched and bent parts. High-quality punching and bending machines depend on components that are absolutely reliable and have a long service life. The bending slide must be robust, reliable and powerful. It should also offer plenty of positioning options. Depending on the production task and the bending machine, our systems consist of multiple bending slides plus different types of bending slides, which can be categorised as schmale bending slides, wide bending slides, double bending slides and under-bending slides. Many punching and bending machines are fitted with sensors to ensure that the bending slides are working properly. Bending slides equipped with quick-clamping systems make it easier to change tools. Changeover times can be significantly reduced by using this type of system, as the tool punch holder can be released by simply loosening the clamping pin. Once loosened, the required tool can be quickly inserted and easily secured again with the clamping pin.

Key aspects with regard to bending slides: tool compatibility and the position on the back wall

In addition to the rated forming force and the maximum stroke, compatibility with a wide range of tools is an important factor when it comes to bending slides. The greater the variety of tools that a bending slide can accept, the wider the range of products that can then be produced on the punching and bending machine. Punching and bending machines from schmale offer the option of mounting the bending slide at any position on the back wall. This means that the bending slide can be set up to work from the rear, or mounted on the table or on consoles from the front. The slide can also be positioned at different angles on the back wall if required. This has the advantage of completely eliminating any jamming, chafing or slipping during the production process. Feather keys are used to prevent the bending slide from slipping on the wall itself. If required, adapters can be screwed between the bending slide and the tools, which also ensures that the required slide position can be regained more quickly. When installing and before commissioning a newly mounted slide, always read and follow the safety and installation instructions for the respective punching/bending machine.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.