production

Rail clip production on the X2000NC

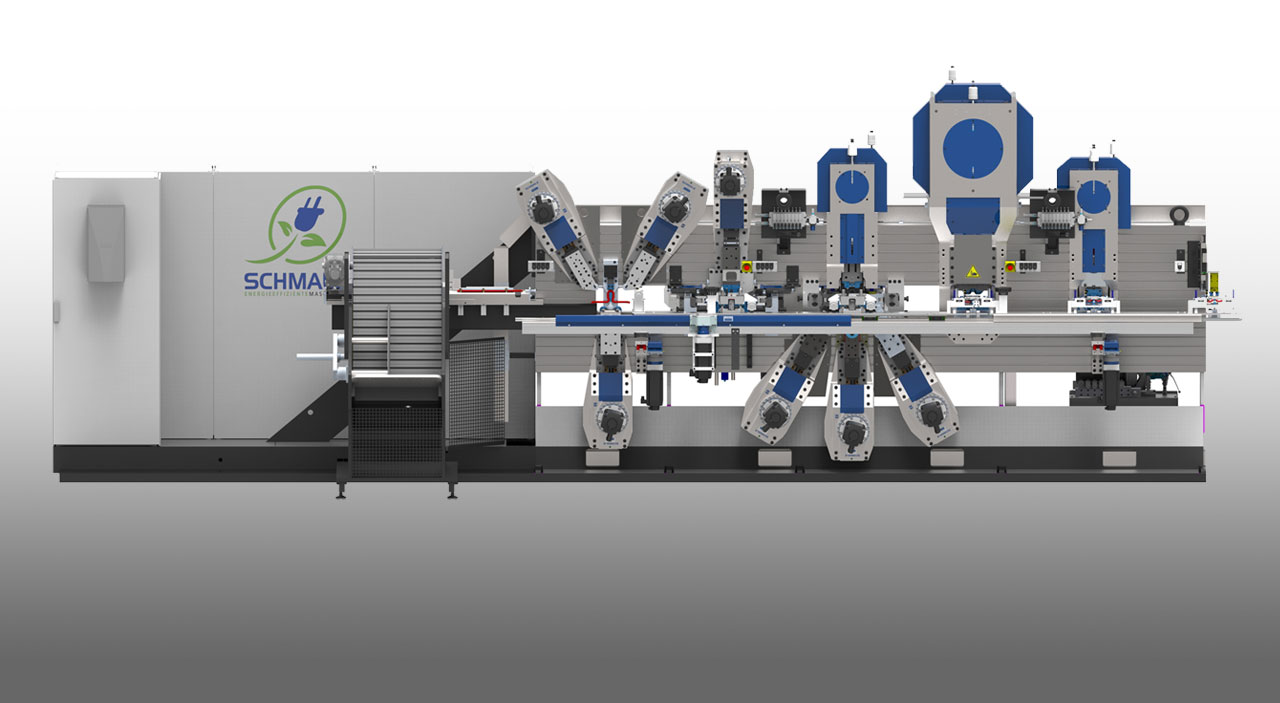

Our X2000NC model wire bending machine is one of the fastest and most compact systems for the production of rail clips. The back wall is only 5 m long and the machine weighs approximately 20 t. The clips pass through several steps and a total of 6 stations as they are cold-formed into their final shape.

The cycle rate for this rail clip line is 30 pcs/minute.

Thanks to its simple retooling mechanism, our X2000NC is capable of producing a wide range of rail clip types.

Technical data

Rail clip production

An illustrative example of a modular tool set on an X2000NC line for the production of rail clips from 12 to 16 mm wire.

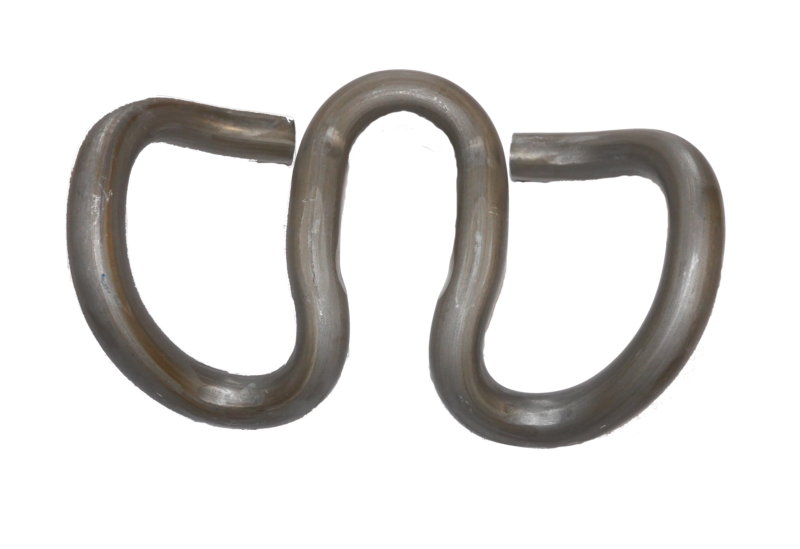

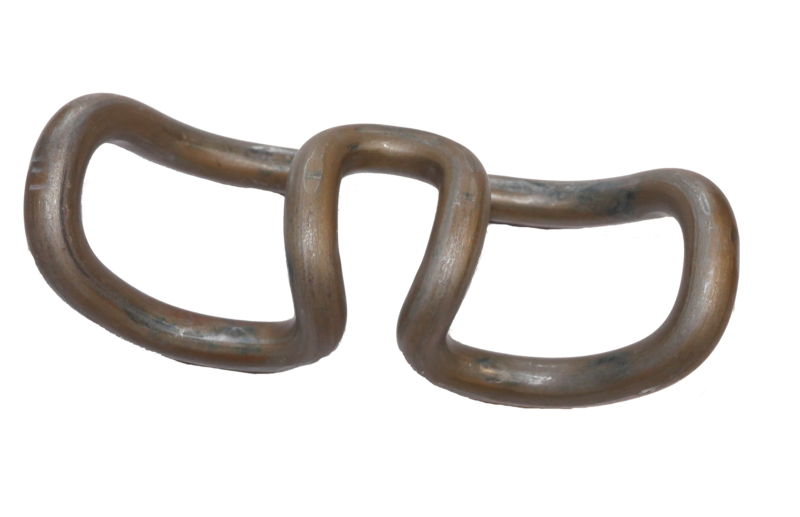

Rail clips or rail clamps have to meet very specific requirements. They must be tough enough to withstand vibrations and temperature fluctuations – and they absolutely must not break. Typically made from 12 to 16 mm-gauge wire, this type of clip typically spends around 50 years holding the rail in place.

Related topics

Clamping ring machines are highly specialised SPECIAL-PURPOSE MACHINES for strip processing. We have a wide range of products in this field, please take a look at our video.

Custom metal forming solutions – the X2000NC from schmale

Rail clips are used to secure rail systems during track construction for railways, tramways and urban rail systems. Also known as rail clamps, these rail fasteners are typically formed by bending 12 to 16 mm-gauge wire. Based on its X2000NC wire bending machine, schmale Maschinenbau GmbH has developed a fully automated bending solution that produces rail clips at high cycle rates with a compact footprint and low energy requirements. The configuration described here can produce 30 ready-to-use rail clips per minute. Different types of rail clips can also be produced on a X2000NC model wire bending machine. A brief retooling and program change is all that is required to start producing a new type of rail clip.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.