X2000NC

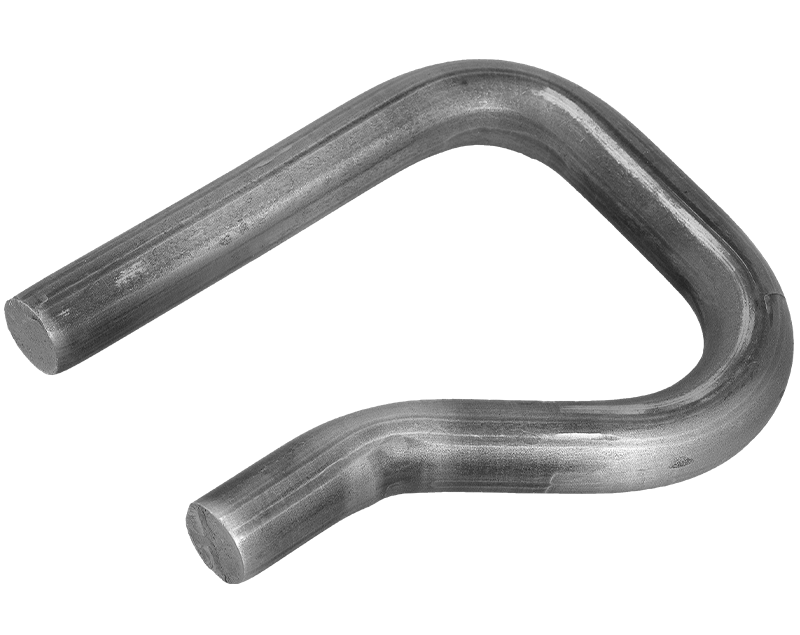

X2000NC for producing door strikers

This version of our X2000NC is the world’s fastest system for producing door strikers for the automotive industry. Different striker shapes can be produced by changing the tool die, along with machining details such as upsetting or tapering at wire ends.

Our unique production model allows cycle times in excess of 60 pcs/minute. For this reason, we’d prefer not to share the technical details of our strategy online. If you’re interested, please arrange a meeting with one of our sales representatives.

Incidentally, we also build assembly systems for coupling door strikers to striker plates.

Technical data

Tool set

Striker sprinter tool, 3 stations, 2 m back wall, coil material fed via NC feed roller.

Our machines operate at high speed. For more information, please contact our Sales department.

Custom metal forming solutions – X2000NC for door striker production

Door strikers (strikes) are used in several places in every passenger car and are an important safety component in motor vehicles. The X2000NC production systems from schmale Maschinenbau GmbH produce door strikers fully automatically at high cycle rates. Bending, flattening and swaging of the wire is carried out in multiple forming processes using bending slides and servo-electric presses. Door striker machines from schmale are used by automotive parts suppliers to produce strikers for virtually every make of car. This is hardly surprising, as our X2000NC – the world’s fastest automotive door striker production system – is considered the gold standard for this type of machine. By changing the tool die, a wide range of striker shapes and sizes can be produced, along with machining details such as upsetting or tapering at the wire ends.

Our unique production model allows cycle times in excess of 60 pieces per minute. In addition to the striker itself, we also design and build assembly systems for the fully automated coupling of door strikers to striker plates, including upset forging or welding.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.