X2000NC-BK

Two worlds combined

Can you imagine using your standard Bihler* tools on a fully servo-electric schmale machine? Are you limited in terms of the amount of force you can generate on your bending machines, which in turn limits the variety of products you can produce? Are you aware of the advantages offered by servo-electric drive technology?

schmale Maschinenbau GmbH has combined the two successful wire bending concepts of schmale and Bihler*.

The X2000NC-BK is a punching/bending machine that is fully compatible with Bihler* tools. Thanks to the schmale machine concept, the X2000NC-BK can be used to produce formed articles that require significantly higher forming forces than those available on original Bihler* systems - such as the grm 50** or grm 80**. Bending slides up to 240 kN and presses with forces up to 2,000 kN can be mounted on schmale's modular X200NC-BK machine.

| Advantages: |

| + Production with virtually no force limitation |

| + NC bending slides up to 240 kN |

| + NC presses up to 2,000 kN |

| + Individually adapted to your requirements |

| + Very simple operation via touch panel |

| + The door to the entire schmale world is open to you too |

| + Modularity and compatibility in the foreground |

*Protected brand name of Otto Bihler Maschinenfabrik GmbH & Co. KG

**grm 50 and grm 80 are protected type designations of systems from Otto Bihler Maschinenfabrik GmbH & Co. KG

schmale

The X2000 NC is more than just a wire/tube bending machine. The X2000 NC, presented by schmale in 2012, is the first fully servo-electric production system. This made the X2000 NC the first machine of its kind to operate without oil or hoses in the area of the drive axes. Since then, the schmale X2000 machine fleet has grown to 4 models: the X2000 NC has been joined by the X2000 NC-BB and the X2000 BK, which is compatible with Bihler tools. In addition, there is the hydro-mechanical X2000 D. The absence of hydraulic oil has had a positive effect on the maintenance requirements of the servo-electric X2000 models, since there is no longer any need to check or clean up any leaking oil. Maintenance tasks such as filling and bleeding hydraulic hoses are also no longer necessary. In terms of set-up times, the servo-electric X2000 models offer significant time savings as there’s no need for mechanical cams. The electronic control system is also easy to operate via touchscreen without the need for any lengthy training. Significant progress has been made with regard to energy saving. For example, the power consumption is about 70% less than that of a servo-hydraulic system.

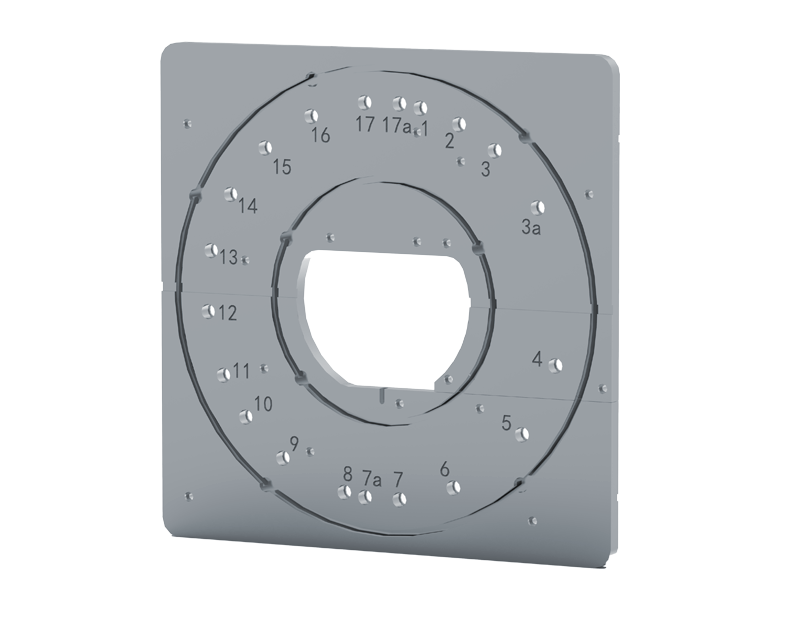

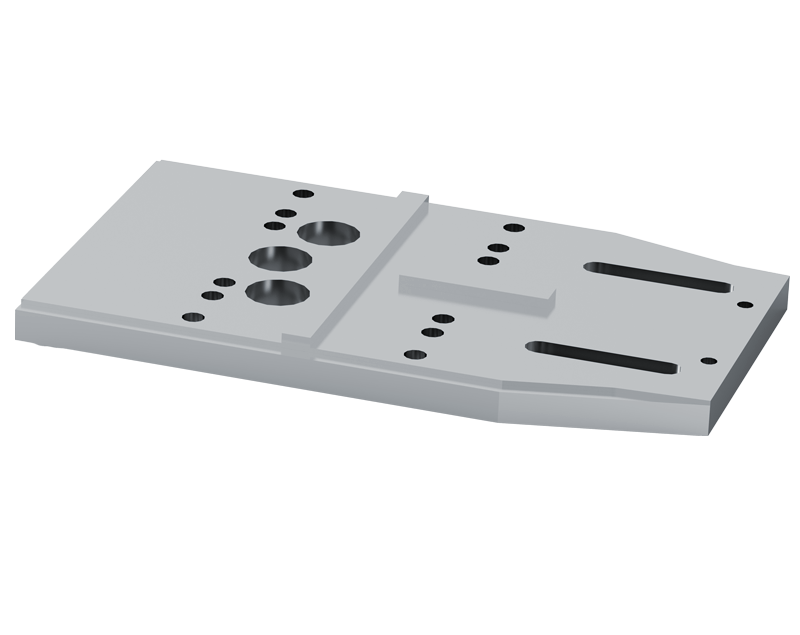

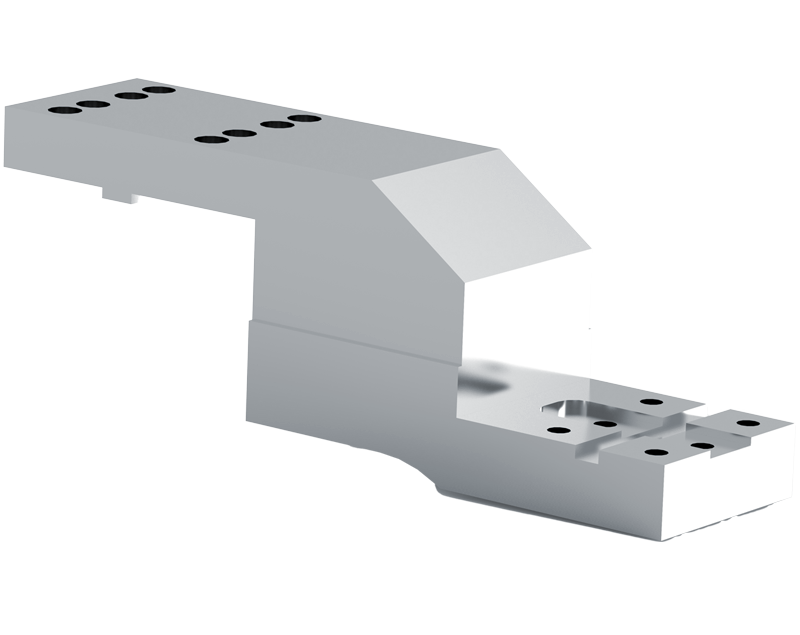

Technology from schmale with Bihler compatibility – The X2000 BK

In response to a number of customer requests, schmale Maschinenbau has developed the X2000 BK, a system that offers compatibility with Bihler tools. The motivation behind this was the need of many customers to have higher bending forces available. This was achieved by converting an X2000 NC wire bending machine from schmale. This was converted using adapter plates to make it compatible with Bihler tools. Forces of up to 240 kN are now possible at the level of the bending slide. If even more force is required, presses of up to 2000 kN can be installed on the X2000 models. The wide range of forming forces makes it possible to process a very wide range of materials. Wire (up to 22 mm), strip steel (up to 5x60 mm) and tubes can all be processed. Cycle rates of up to 200 pieces/minute can be achieved, depending on requirements.

Promptly at your service

The Service department at schmale Maschinenbau GmbH is responsible for technical customer support. Our competent service team is usually available within 24 hours. Error analysis and troubleshooting is often carried out by remote maintenance via our service programmers.

If spare parts and mechanics are required on site, our customers can be sure that they will receive original spare parts and experienced schmale mechanics at short notice.

Of course, we would be more than happy to assist you in person. You can reach us

on weekdays between 8 AM and 4 PM. You can also get in touch with your personal contact.